Style F-013-I

SPIRAL WOUND GASKETS

(WITH CENTERING RING)

F-013-I is used for flanges ASME / ANSI B16.5 (Socket-Weld, Lappe, Welding-Neck and integral flanges.)

They are manufactured under ASME B16.20, API-601 and special measures.

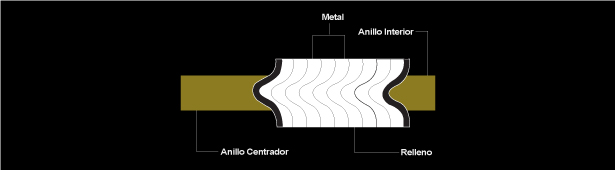

Style F-013 is made up with alternating layers of preformed metal with a filler, which are coiled up.

The interior winding must contain at least three metal layers and unfilled preformed. The first two layers have a minimum of three welds spaced at a distance not less than three inches.

The outer winding must have a minimum of three layers of metal and unfilled preformed with a minimum of three welds, the latter called solder terminal. It is allowed to leave up to four layers of metal parts for adjusting the centering ring gasket.

Style F-013-I is made up with alternating layers of metal with a soft filling, which are coiled up. This part of his package centering ring has an inner ring of the same material as the goal of the package. The inner ring gasket protects the erosion, reducing fluid turbulence and limiting the compression of tightening the screws.

Style F-013-I is specified for high preisón services, high temperatures and corrosive media. As a rule, all filled with Teflon gaskets must have an inner ring. For other fillings the user requested according to their experience and in some instances it has been necessary to include the inner ring.

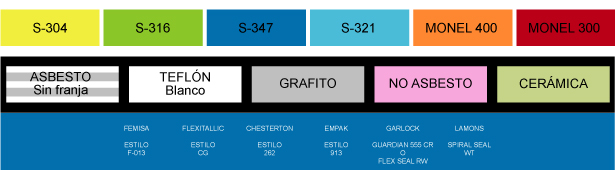

COLOR CODE

The F-013 Style boards, as a rule, are marked with a color code that identifies the materials they are made, such as: cintra Metnal and filling.

- A continuous color on the edge of the centering ring identifies the type of packing material.

- Four slots spaced on the edge of the centering ring identify the fill material of the package.

- For small diameter edge of the ring should have only two slots.

Color code to identify the package:

MATERIALS USED

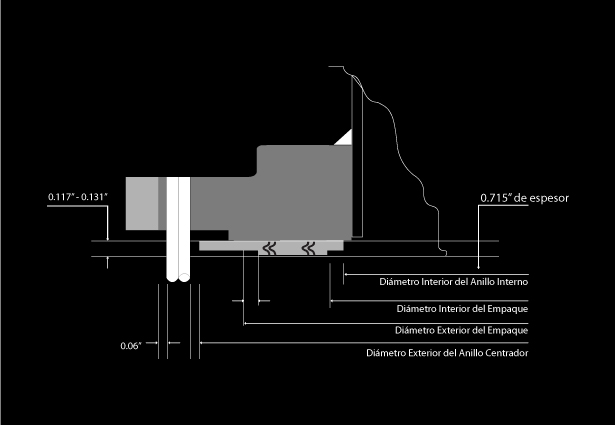

Metal: Monel, Ac. Stainless 304 and Ac. Stainless 316. Thickness: 0.0007 "- 0.0092 Filler: Graphite, Asbestos, Non Asbestos and Teflon. Thickness: .005 ", .020", .031 ", .045". Flange ASME / ANSI B16, 5 and BS1560. They are manufactured with standard thickness of 0.125 "to compress to 0.090" - 0.100.

MARKING: The Style F-013 should be marked on the centering ring with the following information:

1. Nominal size and pressure.

2. Filling material and steel.

3. Manufacturing standard.

4. Brand des manufacturer.

Download Catalog F-013-I